Designing a Warehouse for Maximum Efficiency and Productivity

Warehouses are the backbone of any successful business that deals with physical products. The efficiency and productivity of a warehouse directly impact the overall performance of the supply chain and, ultimately, the bottom line of the company. Designing a warehouse for maximum efficiency and productivity is a strategic process that requires careful planning and consideration of various factors. By optimizing the layout, storage systems, technology integration, and workflow processes, businesses can streamline operations and enhance their competitive edge in the market.

Optimizing Layout and Workflow

One of the key aspects of designing a warehouse for maximum efficiency is optimizing the layout and workflow. The layout should be designed in a way that minimizes travel time and maximizes space utilization. This can be achieved by strategically placing high-demand items closer to the shipping area and keeping frequently accessed items easily accessible. Implementing a logical flow of goods from receiving to storage to picking and packing areas can reduce congestion and improve overall efficiency.

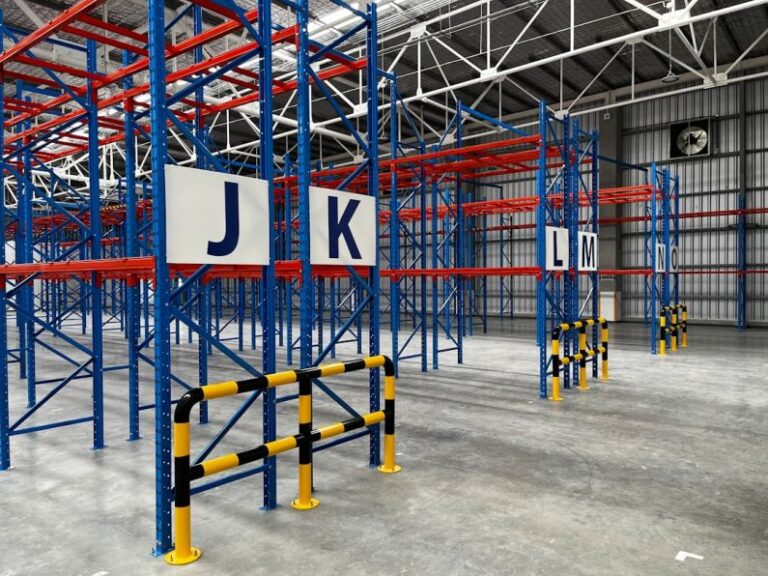

Utilizing Vertical Space

Maximizing the use of vertical space is essential for creating an efficient warehouse design. By utilizing tall storage racks and shelving systems, businesses can store more products in a smaller footprint. Vertical storage solutions not only increase storage capacity but also make it easier for warehouse personnel to locate and retrieve items quickly. Implementing mezzanine levels or multi-tier shelving systems can further optimize vertical space and improve overall productivity.

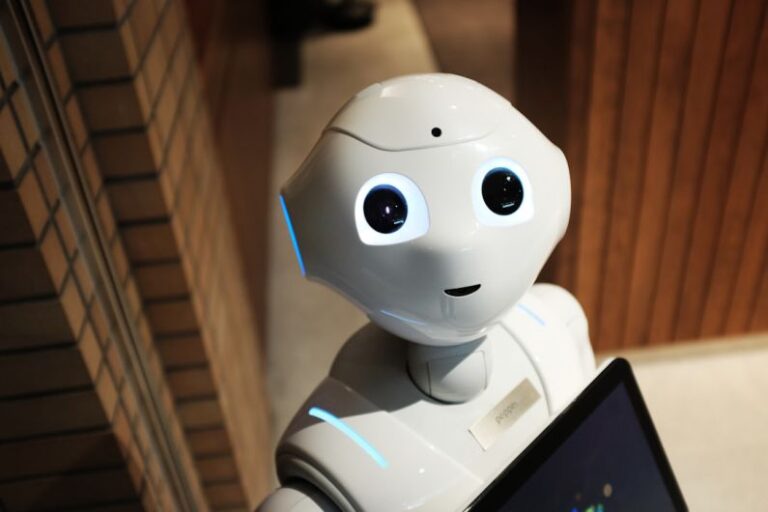

Implementing Technology Solutions

In today’s digital age, integrating technology solutions into warehouse design is crucial for achieving maximum efficiency and productivity. Automation systems such as conveyor belts, automated guided vehicles (AGVs), and robotic picking systems can significantly reduce manual labor and streamline operations. Warehouse management systems (WMS) and inventory tracking software can help businesses track inventory levels in real-time, optimize picking routes, and improve order accuracy.

Enhancing Safety and Security

Ensuring the safety and security of warehouse operations is paramount when designing a warehouse for maximum efficiency. Implementing proper lighting, clear signage, and designated walkways can help prevent accidents and injuries. Installing security cameras, access control systems, and alarm systems can protect valuable inventory and assets from theft or unauthorized access. By creating a safe and secure work environment, businesses can boost employee morale and productivity.

Continuous Improvement and Adaptability

Designing a warehouse for maximum efficiency is an ongoing process that requires continuous improvement and adaptability. Regularly reviewing and analyzing key performance indicators (KPIs) such as order fulfillment rates, inventory turnover, and labor productivity can help identify areas for improvement. By staying flexible and responsive to changing market trends and customer demands, businesses can adapt their warehouse design to meet evolving needs and maintain a competitive edge.

Maximizing Efficiency and Productivity in Your Warehouse

In conclusion, designing a warehouse for maximum efficiency and productivity is a multifaceted process that involves optimizing layout and workflow, utilizing vertical space, implementing technology solutions, enhancing safety and security, and fostering a culture of continuous improvement. By strategically planning and implementing these key principles, businesses can create a warehouse environment that drives operational excellence, improves customer satisfaction, and ultimately contributes to the success of the overall supply chain. Investing in warehouse design is not just about physical space; it is an investment in the future growth and sustainability of the business.