Implementing an Efficient Warehouse Management System

In the fast-paced world of logistics and supply chain management, having an efficient warehouse management system (WMS) is crucial to the success of any business. A well-implemented WMS can streamline operations, improve inventory accuracy, and boost overall productivity. By utilizing the right technology and strategies, companies can optimize their warehouse processes and stay ahead of the competition.

**Selecting the Right WMS Software**

When it comes to implementing a successful WMS, choosing the right software is key. There are many WMS solutions available in the market, each offering unique features and capabilities. It is essential to assess your specific business needs and objectives before selecting a WMS that aligns with your requirements. Look for software that offers real-time inventory tracking, order management, and integration with other systems such as Enterprise Resource Planning (ERP) software.

**Training and Onboarding Staff**

Implementing a new WMS involves training and onboarding staff to ensure a smooth transition. Proper training is essential to help employees understand how to use the system effectively and efficiently. Providing comprehensive training sessions and ongoing support will empower employees to make the most of the WMS and maximize its benefits. Additionally, involving staff in the implementation process can increase buy-in and promote a positive attitude towards the new system.

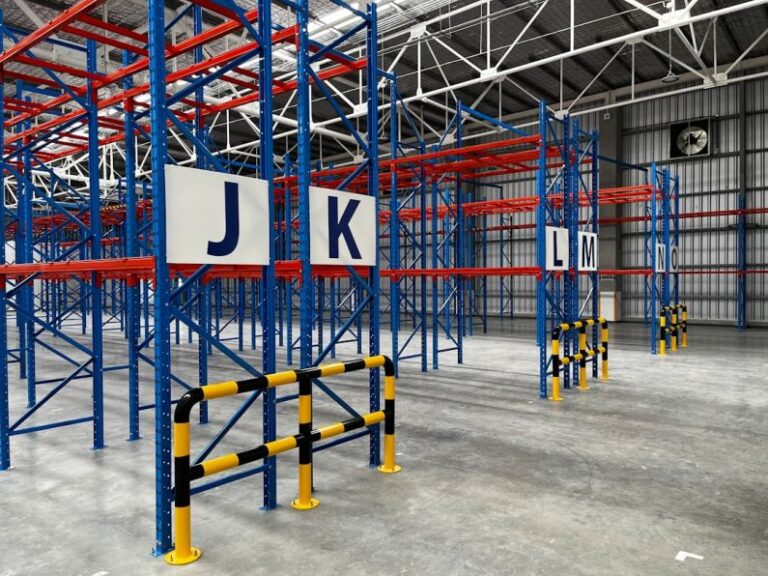

**Optimizing Warehouse Layout and Processes**

To make the most of your WMS, it is crucial to optimize your warehouse layout and processes. A well-organized warehouse layout can improve workflow efficiency and reduce errors. Consider factors such as item popularity, order picking paths, and storage capacity when designing your warehouse layout. Implementing lean principles, such as 5S methodology, can help eliminate waste and streamline operations.

**Utilizing Automation and Technology**

Automation and technology play a significant role in enhancing warehouse efficiency. Utilizing technologies such as barcode scanning, RFID, and automated storage and retrieval systems can improve inventory accuracy and speed up order fulfillment. Integrating these technologies with your WMS can further enhance visibility and control over warehouse operations. Leveraging data analytics and reporting tools can provide valuable insights for optimizing processes and making informed decisions.

**Continuous Monitoring and Improvement**

Implementing an efficient WMS is an ongoing process that requires continuous monitoring and improvement. Regularly review key performance indicators (KPIs) such as order accuracy, inventory turnover, and order fulfillment times to identify areas for improvement. Conduct regular audits to ensure data accuracy and system reliability. Solicit feedback from staff and stakeholders to gather insights for enhancing the system further.

**Enhancing Customer Experience**

A well-implemented WMS not only benefits internal operations but also enhances the overall customer experience. By improving order accuracy, reducing lead times, and providing real-time order tracking, businesses can deliver superior service to their customers. A seamless order fulfillment process can lead to increased customer satisfaction, repeat business, and positive word-of-mouth referrals.

**Driving Business Growth**

Implementing an efficient warehouse management system is not just about optimizing current operations but also laying the foundation for future growth. A scalable WMS can accommodate business expansion and evolving market demands. By investing in the right technology and strategies, businesses can position themselves for long-term success and stay competitive in a rapidly changing landscape.

**In Summary**

Implementing an efficient warehouse management system is a strategic investment that can yield significant benefits for businesses of all sizes. By selecting the right software, training and onboarding staff, optimizing warehouse layout and processes, utilizing automation and technology, monitoring performance, enhancing customer experience, and driving business growth, companies can streamline operations, improve efficiency, and ultimately, achieve success in today’s dynamic marketplace.