The Importance of Warehouse Safety Measures

Warehouse safety measures are of utmost importance in any industrial setting to ensure the well-being of employees and the efficient functioning of operations. With the constant movement of goods, heavy equipment, and machinery within a warehouse, the potential for accidents and injuries is high. Implementing and strictly adhering to safety protocols is crucial to mitigate risks and create a secure working environment for all personnel involved.

**The Role of Warehouse Safety**

Ensuring warehouse safety is not just a legal requirement but also a moral obligation for companies. By prioritizing the well-being of their employees, organizations can foster a culture of safety consciousness that permeates through all levels of the workforce. Safety measures in a warehouse not only protect employees from harm but also safeguard company assets and maintain productivity levels by reducing downtime caused by accidents.

**Preventive Measures**

One of the key aspects of warehouse safety is the implementation of preventive measures. This includes regular maintenance of equipment and machinery to ensure they are in optimal working condition. Conducting routine safety inspections and risk assessments can help identify potential hazards and address them before they escalate into accidents. Providing adequate training to employees on safe handling practices, proper use of equipment, and emergency procedures is essential in preventing mishaps in the warehouse environment.

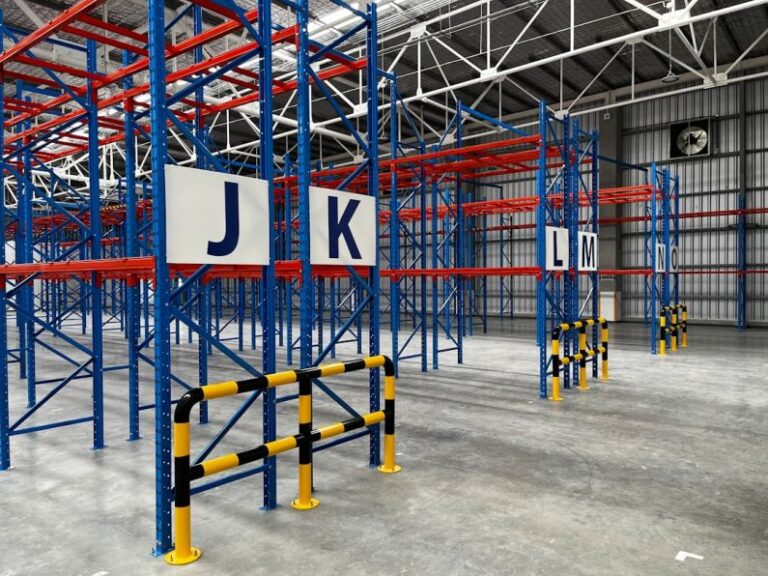

**Proper Signage and Organization**

Clear and visible signage throughout the warehouse plays a vital role in guiding employees on safety protocols, hazard warnings, and emergency exits. Proper organization of the workspace, including designated storage areas, walkways, and loading zones, can help reduce clutter and minimize the risk of trips, falls, and collisions. Maintaining a clutter-free environment not only enhances safety but also improves operational efficiency by enabling smooth movement of goods and personnel within the warehouse.

**Personal Protective Equipment (PPE)**

The use of appropriate personal protective equipment is non-negotiable in a warehouse setting. Employees working in areas where there is a risk of injury from falling objects, moving machinery, or hazardous substances must be provided with and required to wear PPE such as hard hats, safety goggles, gloves, and steel-toed boots. Ensuring that PPE is readily available and properly maintained is essential to protect workers from potential harm and minimize the severity of injuries in the event of an accident.

**Emergency Preparedness**

In the event of an emergency, quick and effective response can mean the difference between a minor incident and a major catastrophe. Developing and regularly practicing emergency response plans, including procedures for evacuations, fire drills, and first aid, is crucial in ensuring the safety of everyone in the warehouse. Having clearly marked emergency exits, accessible fire extinguishers, and designated assembly points can help expedite the response to emergencies and prevent injuries or loss of life.

**Continuous Training and Improvement**

Safety in the warehouse is an ongoing process that requires continuous training, education, and improvement. Providing regular refresher courses on safety protocols, conducting mock drills, and soliciting feedback from employees on potential safety concerns can help identify areas for improvement and reinforce a culture of safety within the organization. Encouraging employees to report near misses, hazards, or unsafe practices without fear of reprisal is essential in maintaining a proactive approach to safety in the warehouse.

**Safeguarding Success: The Future of Warehouse Safety**

As technology advances and warehouse operations become more sophisticated, the importance of safety measures cannot be overstated. Embracing innovations such as automated systems, robotics, and IoT devices can enhance efficiency and productivity in the warehouse, but they also bring new safety challenges that must be addressed. Companies that prioritize warehouse safety not only protect their most valuable asset—their employees—but also position themselves for long-term success by minimizing risks, reducing costs associated with accidents, and fostering a positive work environment.

Warehouse safety measures are not just a regulatory requirement; they are a strategic investment in the well-being of employees and the sustainability of operations. By implementing preventive measures, providing proper training and equipment, and fostering a culture of safety, companies can create a secure and productive warehouse environment that benefits everyone involved. In a world where safety is paramount, prioritizing warehouse safety is not just a choice—it’s a necessity for success.