The Role of 3d Printing in Supply Chain Management

In today’s fast-paced and dynamic business environment, supply chain management plays a crucial role in determining the success of a company. The traditional methods of manufacturing and distribution are constantly evolving to meet the demands of the market. One such technological advancement that has revolutionized supply chain management is 3D printing.

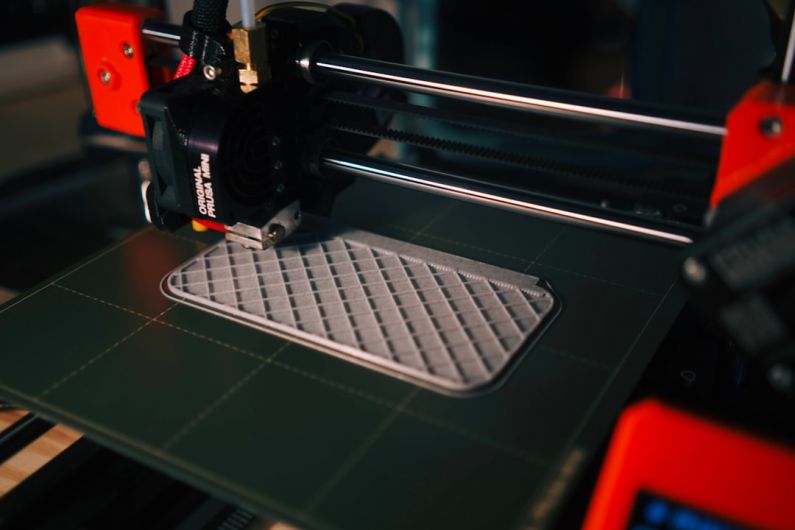

Revolutionizing Manufacturing Processes

3D printing, also known as additive manufacturing, is a process that creates three-dimensional objects by adding material layer by layer based on a digital model. This technology has transformed the way products are designed, prototyped, and manufactured. By enabling on-demand production of parts and products, 3D printing has significantly reduced lead times and made supply chains more agile and responsive to changing market demands.

Reducing Inventory Costs

One of the key benefits of incorporating 3D printing into supply chain management is the significant reduction in inventory costs. Traditional manufacturing processes often require companies to maintain high levels of inventory to meet production demands. With 3D printing, companies can produce parts and products as needed, eliminating the need for large warehouses and excess inventory. This just-in-time production model not only reduces storage costs but also minimizes the risk of obsolete inventory.

Customization and Personalization

3D printing allows for a high level of customization and personalization that traditional manufacturing methods cannot achieve. Companies can easily modify product designs to meet specific customer requirements without incurring additional costs or lead times. This level of flexibility enables companies to offer unique products tailored to individual customer needs, giving them a competitive edge in the market.

Supply Chain Resilience

The COVID-19 pandemic highlighted the importance of supply chain resilience, with disruptions causing delays in production and distribution across industries. Companies that had adopted 3D printing in their supply chain management were better equipped to navigate these challenges. The ability to quickly pivot production to meet changing demands and produce essential items on-site helped these companies maintain business continuity during uncertain times.

Localized Production

3D printing enables localized production, allowing companies to establish smaller manufacturing facilities closer to their customers. This not only reduces transportation costs and lead times but also minimizes the environmental impact associated with long-distance shipping. By decentralizing production through 3D printing, companies can create a more sustainable and efficient supply chain network.

Supply Chain Optimization

Integrating 3D printing into supply chain management offers opportunities for optimization at every stage of the production process. From reducing material waste and energy consumption to streamlining logistics and distribution, 3D printing provides a more sustainable and cost-effective solution for companies looking to enhance their supply chain operations. By leveraging the benefits of 3D printing, companies can achieve greater efficiency and competitiveness in the market.

Innovative Supply Chain Strategies

As companies continue to explore the potential of 3D printing in supply chain management, new innovative strategies are emerging. From digital inventory management to decentralized production hubs, organizations are reimagining traditional supply chain models to leverage the advantages of additive manufacturing. By embracing these cutting-edge technologies, companies can stay ahead of the curve and adapt to the ever-changing demands of the market.

Embracing the Future of Supply Chain Management

The role of 3D printing in supply chain management is not just a trend but a transformative technology that is reshaping the way companies design, produce, and distribute goods. By harnessing the power of additive manufacturing, companies can unlock new opportunities for growth, efficiency, and sustainability in their supply chain operations. As the technology continues to evolve, organizations that embrace 3D printing will be better positioned to thrive in an increasingly competitive and dynamic business landscape.