The Role of Quality Control in Supply Chain Management

In the fast-paced world of supply chain management, maintaining quality control is paramount to ensure efficiency, customer satisfaction, and overall success. From raw material procurement to final product delivery, every step in the supply chain must meet stringent quality standards to uphold the reputation of the company and meet the expectations of consumers. Quality control plays a crucial role in streamlining operations, reducing costs, and mitigating risks along the supply chain.

The Foundation of Quality Control

Quality control is the process of ensuring that products or services meet specified quality standards and requirements. It involves monitoring and inspecting every phase of the production process to identify and rectify any deviations from the set quality parameters. By implementing robust quality control measures, companies can prevent defects, minimize wastage, and enhance product consistency.

Enhancing Supplier Relationships

One of the key aspects of supply chain management is maintaining strong relationships with suppliers. Quality control mechanisms help in establishing clear expectations and guidelines for suppliers, ensuring that they deliver materials or components that meet the required quality standards. By working closely with suppliers to monitor and improve quality, companies can reduce the risk of disruptions and delays in the supply chain.

Ensuring Product Integrity

Quality control is instrumental in safeguarding the integrity of the products throughout the supply chain. By conducting rigorous inspections and tests at various stages of production, companies can identify any issues early on and take corrective actions to prevent substandard products from reaching the market. This proactive approach not only protects the brand reputation but also helps in meeting regulatory compliance and customer expectations.

Managing Risk and Compliance

In today’s global supply chains, the regulatory landscape is constantly evolving, posing challenges for companies to ensure compliance with various quality and safety standards. Quality control measures help in identifying potential risks and ensuring that products meet the necessary regulatory requirements. By staying abreast of changing regulations and conducting thorough quality checks, companies can mitigate legal risks and avoid costly penalties.

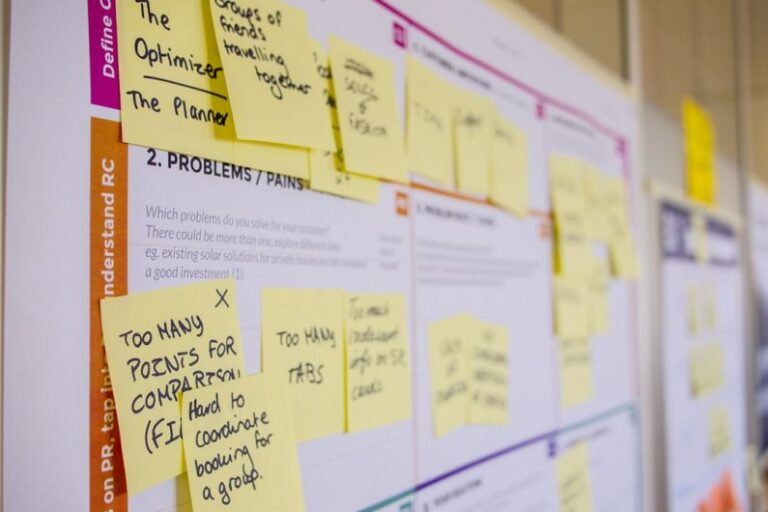

Improving Operational Efficiency

Efficient supply chain management relies on seamless coordination and collaboration among various stakeholders involved in the process. Quality control plays a vital role in optimizing operational efficiency by identifying bottlenecks, eliminating waste, and improving processes. By implementing quality control tools such as Six Sigma or Total Quality Management, companies can streamline operations, enhance productivity, and drive continuous improvement.

Enhancing Customer Satisfaction

At the heart of every supply chain is the end customer whose satisfaction is paramount for the success of any business. Quality control ensures that products meet or exceed customer expectations in terms of quality, performance, and reliability. By consistently delivering high-quality products, companies can build trust and loyalty among customers, leading to repeat business and positive word-of-mouth referrals.

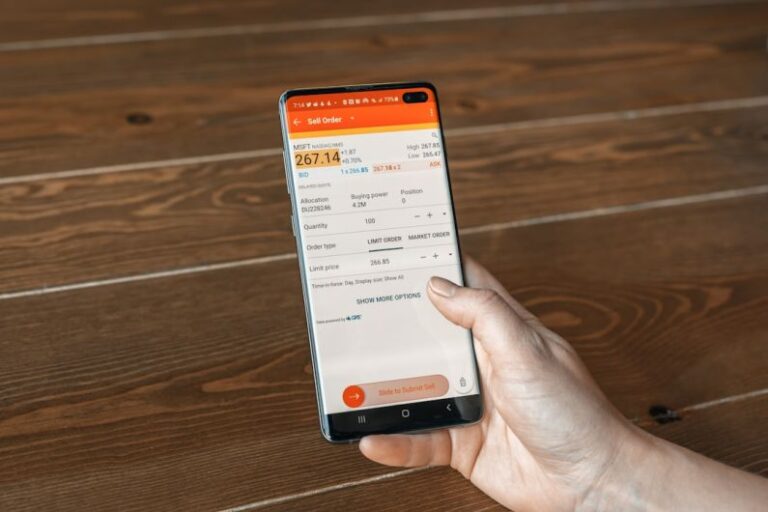

Embracing Technology and Innovation

In the digital age, technology plays a pivotal role in revolutionizing supply chain management practices. Quality control tools such as automated inspection systems, data analytics, and real-time monitoring software enable companies to track and analyze quality metrics in real-time. By leveraging technology and embracing innovation, companies can enhance visibility, traceability, and control over the entire supply chain, driving operational excellence and competitive advantage.

In conclusion, quality control is the linchpin of effective supply chain management, ensuring that products meet stringent quality standards, regulatory requirements, and customer expectations. By implementing robust quality control measures, companies can optimize operations, mitigate risks, and enhance the overall efficiency and performance of their supply chain. In today’s dynamic business environment, investing in quality control is not just a necessity but a strategic imperative for companies looking to stay ahead of the competition and deliver value to customers.