Cost Reduction Techniques in Warehousing

In today’s competitive business landscape, companies are constantly looking for ways to reduce costs while maintaining efficiency. Warehousing plays a crucial role in the supply chain, and optimizing operations in this area can lead to significant cost savings. By implementing cost reduction techniques in warehousing, businesses can streamline processes, increase productivity, and ultimately improve their bottom line.

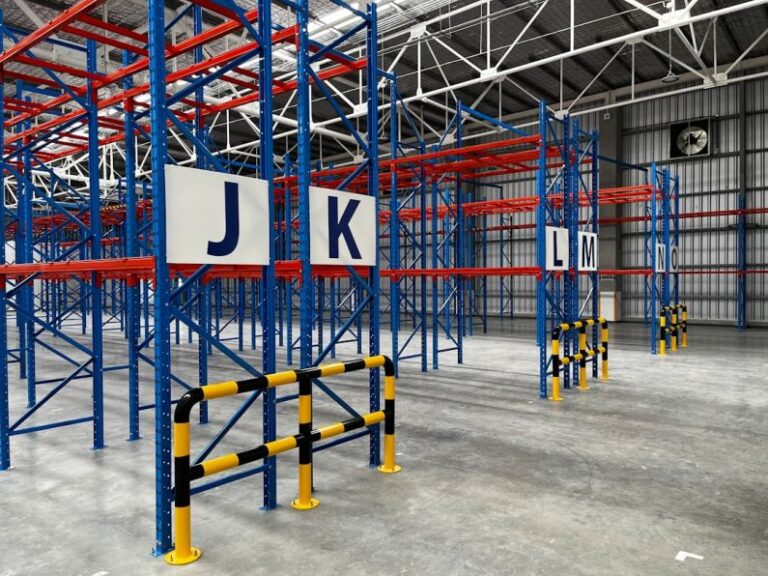

Optimizing Warehouse Layout

The layout of a warehouse can have a significant impact on its efficiency and operational costs. By strategically organizing the placement of storage racks, equipment, and workstations, companies can minimize the time and effort required to fulfill orders. Implementing a layout that promotes a smooth flow of goods from receiving to shipping can help reduce travel time for workers and minimize the risk of errors. Additionally, utilizing vertical space efficiently through mezzanine levels or high stacking can maximize storage capacity without the need for costly expansions.

Utilizing Technology

Advancements in technology have revolutionized the way warehouses operate, offering numerous tools and systems to improve efficiency and reduce costs. Implementing a warehouse management system (WMS) can help automate processes such as inventory tracking, order picking, and replenishment, leading to fewer errors and faster turnaround times. Utilizing barcode scanners and RFID technology can streamline receiving and picking operations, reducing the time and labor required to manage inventory. Furthermore, automated guided vehicles (AGVs) and robotic systems can help optimize material handling processes, increasing productivity and reducing reliance on manual labor.

Implementing Lean Principles

Applying lean principles to warehouse operations can help identify and eliminate waste, ultimately reducing costs and improving efficiency. By streamlining processes and eliminating non-value-added activities, companies can optimize their workflows and minimize unnecessary expenses. Implementing practices such as 5S (Sort, Set in order, Shine, Standardize, Sustain) can help maintain a clean and organized workspace, improving safety and efficiency. Additionally, adopting just-in-time (JIT) inventory management can help reduce excess inventory holding costs and minimize the risk of stockouts.

Outsourcing Non-core Activities

Outsourcing non-core activities such as packaging, labeling, and transportation can help reduce costs and free up internal resources to focus on core business functions. By partnering with third-party logistics providers (3PLs), companies can benefit from their expertise and infrastructure, gaining access to specialized services and cost-effective solutions. Outsourcing can help companies scale their operations according to demand fluctuations, avoiding the need for large capital investments in warehouse facilities and equipment. Additionally, 3PLs can offer value-added services such as cross-docking, kitting, and reverse logistics, further optimizing supply chain operations.

Continuous Improvement

Continuous improvement is a key principle in cost reduction techniques in warehousing. By regularly reviewing and analyzing operational performance, companies can identify areas for improvement and implement changes to drive efficiency and reduce costs. Conducting regular audits of inventory levels, order accuracy, and cycle times can help pinpoint inefficiencies and bottlenecks in warehouse operations. By soliciting feedback from employees and stakeholders, companies can gain valuable insights into potential areas for improvement and implement targeted solutions to drive cost savings.

Cost Reduction Techniques in Warehousing: A Roadmap to Operational Excellence

In conclusion, implementing cost reduction techniques in warehousing is essential for companies looking to optimize their operations and stay competitive in today’s market. By focusing on optimizing warehouse layout, utilizing technology, implementing lean principles, outsourcing non-core activities, and continuously improving operations, businesses can drive efficiency, reduce costs, and enhance their overall performance. Embracing a culture of continuous improvement and innovation is crucial for companies seeking to achieve operational excellence and sustain long-term success in the dynamic world of warehousing.